A day in Colmar together with Liebherr

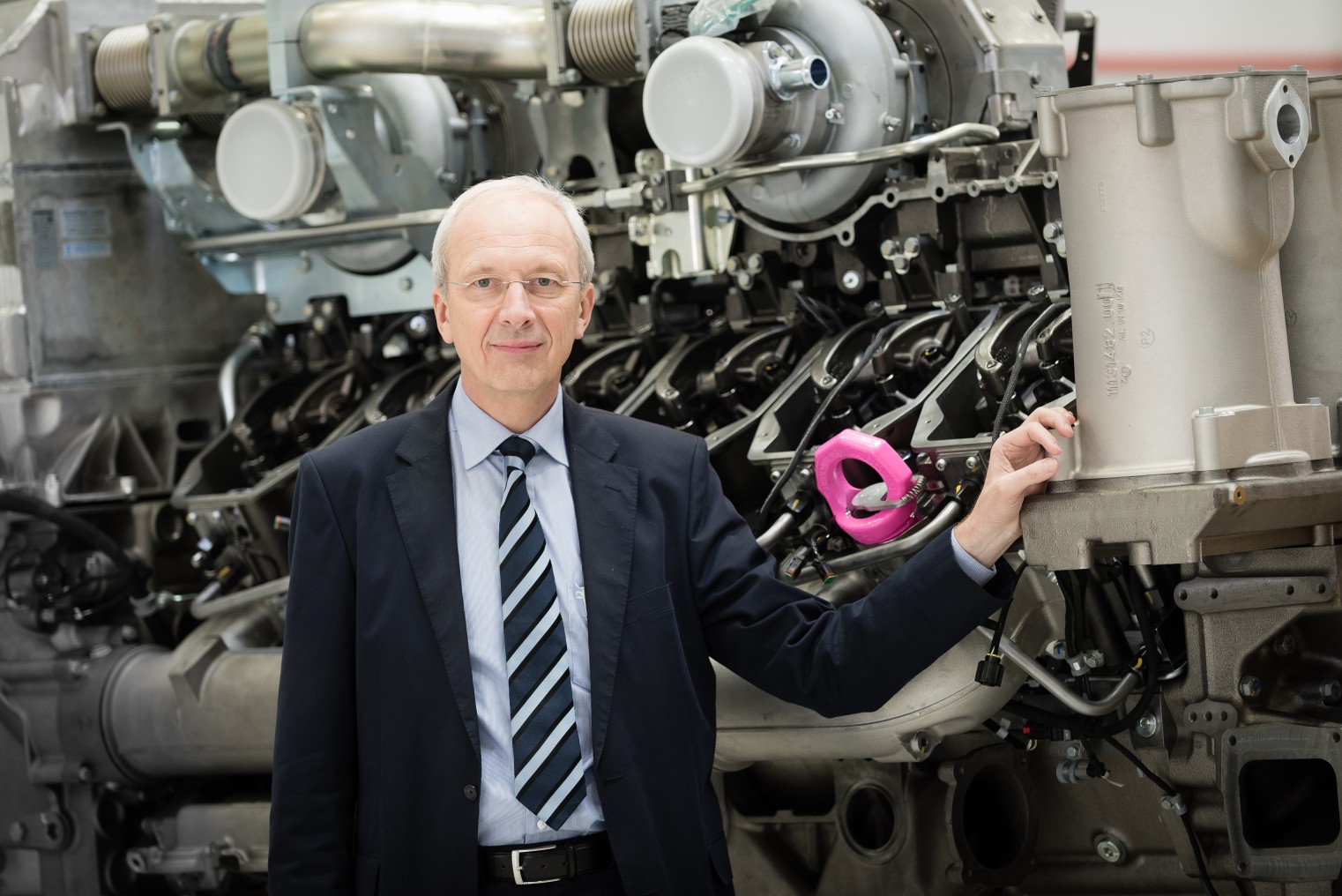

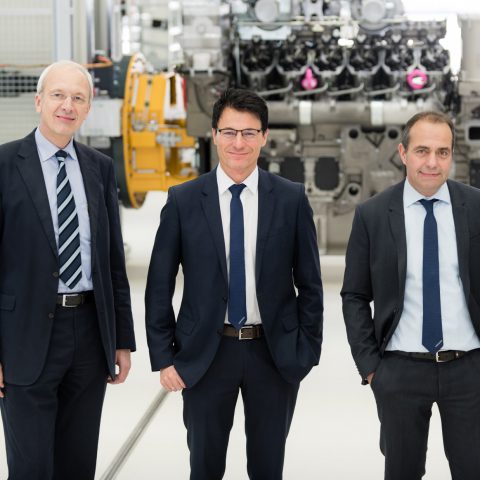

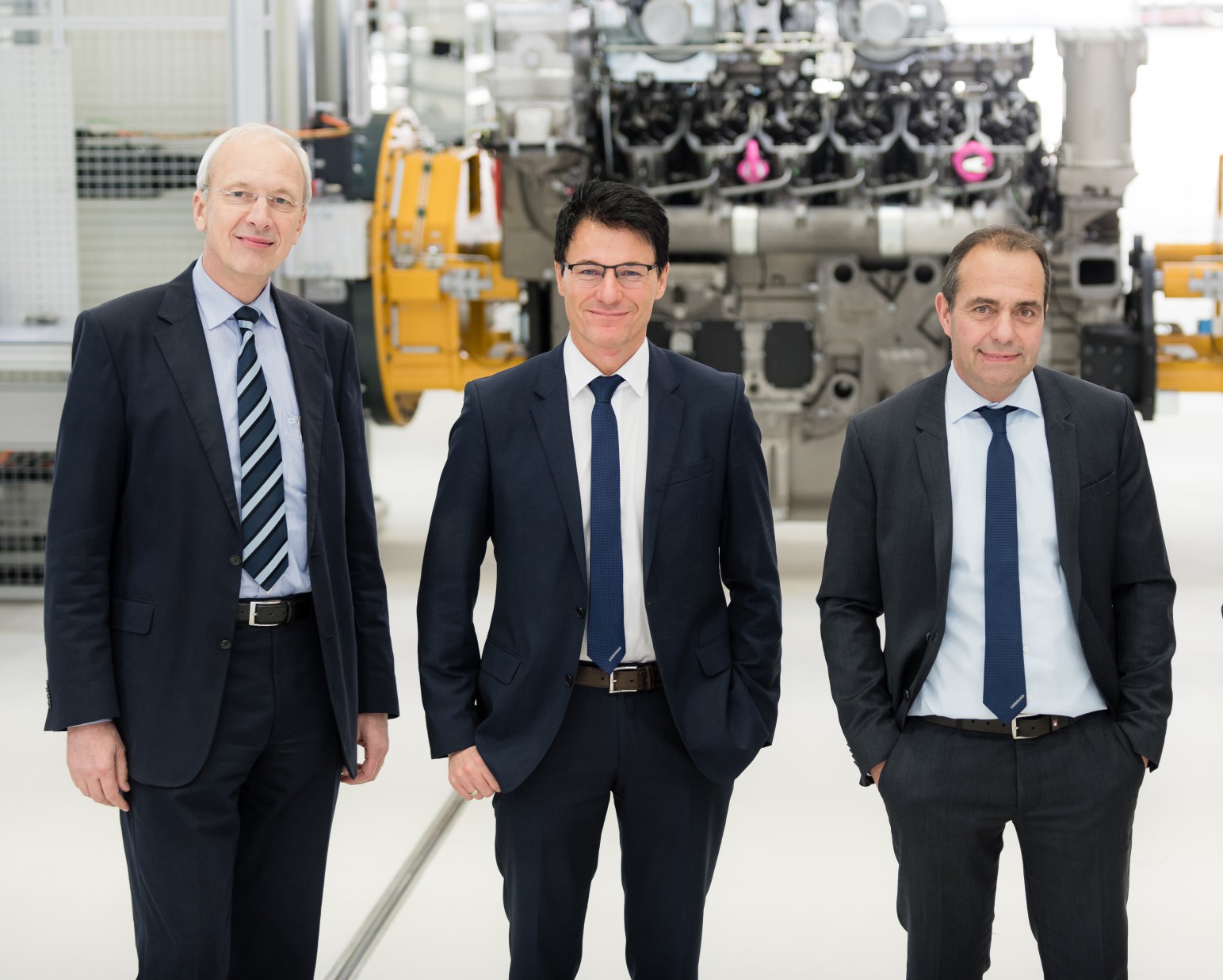

We are in Colmar, Alsace, a charming corner of France that shares with Germany the urban atmosphere, the river Rhine and the skills in mechanics industry. Liebherr Components chose this location as the hometown of the D98XX engine series. We talked about it with an exceptional trio from Liebherr management: Diethard Plohberger, Ingo Wintruff and […]

We are in Colmar, Alsace, a charming corner of France that shares with Germany the urban atmosphere, the river Rhine and the skills in mechanics industry. Liebherr Components chose this location as the hometown of the D98XX engine series. We talked about it with an exceptional trio from Liebherr management: Diethard Plohberger, Ingo Wintruff and Jens Krug. The full interview will be published on DIESEL July-August issue and DIESEL International November issue.

Colmar and D9812

Would you please briefly describe the technological genesis of this engine?

Mr. Plohberger: The D9812 engine has been designed basically as a mine engine. This means a rugged design for challenging environments like dust, heat, humidity, heavy vibrations, etc. It is a perfect prerequisite for deriving the D98XX engine series design for other applications, like power generation, etc. To ensure this and achieve low production cost, low parts stock requirement and ease of maintenance, the engine has been strictly designed according to the tool box principle. The core engine and the auxiliary components are standardized and built in modules.

Diesel of the year prize means first of all innovation. What are the innovative features of D9812, Diesel of the year 2017?

Mr. Plohberger: The D9812 engine features 20% more power density than benchmark engines in the market. The high peak firing pressure capability of 250 bars makes it perfectly suitable to fulfill the new exhaust emission limits in the US (EPA Tier4) and Europe (EU Stage V) with simultaneously very good fuel consumption. The standardized and module based design allows different applications at minimum design adaptions.

D98 vs competitors

Can you compare the D9812 with its main competitors (i.e. MTU and Cummins)?

Mr. Wintruff: The D98XX is a brand new series. Some of the competitors’ engines in the market were developed 20 or 30 years ago. Using state of the art technology, our engine will set the benchmark in the market in terms of efficiency and power density. To reach this target we use, for example, modern common rail injection system, advanced turbocharging technology, high peak firing pressure capability, a down-speeding option for further efficiency improvement, as well as a down-sizing option, in order to offer cost advantages in existing machines, for example.

Which are the terms of the agreement with Kohler for power gen version?

Krug: Kohler and Liebherr are strategic partners collaborating to design highly efficient engines for new industrial generator line since 2008. The G-Drive Application features have been co-developed by Kohler and Liebherr and have been tested under rigorous operating conditions. These features are exclusively developed for power generation to ensure optimal voltage and frequency performance as required in this application.